Over the course of three capital projects, GS Caltex celebrates dramatic results

The IIF journey was implemented in three phases to create a thriving safety culture.

The IIF journey was implemented in three phases to create a thriving safety culture.

Since 2004, GS Caltex has undertaken three major megaprojects constructing Heavy Oil Upgrade facilities. VGO HCR, the first of these—and the first implementation of the IIF approach in the country—was a billion dollar project with over 6000 workers. While the goal of GS Caltex management was to complete the project as safely as possible, there were a number of initial concerns. At the time throughout the country, there was the general perception among Engineering, Procurement and Construction contractors that a focus on safety got in the way of production, and that the financial costs would outweigh the benefits. Because Korea’s construction industry was so heavily schedule driven, these concerns posed some doubts about the IIF™ Safety approach.

Along with this, there were other initial concerns on the parts of workers and contractors: that the IIF Safety approach might not be suitable for the Asian culture, that a project without incidents and injuries would not be possible on a project of that size, and that the IIF Safety approach might just be window dressing rather than a genuine commitment. There was also the mindset of some contractors on the project that the IIF Safety approach was an obligation handed down by GS Caltex rather than something worth taking ownership over.

Along with the general demands that such projects set forward, the overall construction culture throughout the country proved challenging for worker safety. Often worker facilities were in poor condition. There were few, if any, worker rest areas, and communication was usually very authoritative rather than cooperative.

The GS Caltex IIF journey has been implemented in three phases over the course of the three megaprojects. The first project saw a top-down introduction to the IIFapproach, the second was integration into the overall GS Caltex culture, and the third project has seen a thriving, active IIF culture.

During the first phase, JMJ delivered six two-day workshops to 178 managers and site leaders initiating them into the IIF approach and engaging their commitment to no incidents and injuries. This extended into the formation of a site IIF leadership team led by GS Caltex staff. This led to IIF train-the-trainers events preparing site staff to orient others to the IIF approach, Town Hall meetings every month, and IIF orientations led by GS Caltex and delivered to all personnel.

As a result of this, GS Caltex and site workers created Recognition Awards for strong IIF performance, IIF nights, safety campaigns and magazines, and regular coaching.

While the foundation was laid during the first megaproject, the second was an opportunity to strengthen the IIF culture and bring a focus on middle management. This led to ongoing programs strengthening managements’ understanding of the IIF approach, supervisor skills training and monthly IIF coaching by JMJ consultants, along with two-day workshops to ensure site leadership was engaged with the commitment to no incidents and injuries. A mentor program was created that allowed staff to guide other workers towards a more full understanding of the safety approach, and there was a clear visual identity throughout the site that strengthened the integration of IIFsafety into the GS Caltex culture.

“JMJ helped change the mindset and perspective of workers on the project,” said Mr. Dong-Wan

Woo, Construction Manager/Senior Manager, GS Caltex VGO FCC Project, GS Engineering & Construction. “There were very systematic programs. Not only did they hold workshops that helped change our mindset, but they followed up on workshops with group coaching. Because it was a constant process and there were regular trainings and coaching, it helped people be reminded of the IIF [approach] constantly.”

By the time the third megaproject began, the IIF culture had taken hold, and GS Caltex and JMJ were in a position to raise the bar on the safety culture with similar workshops and trainings, which continue today.

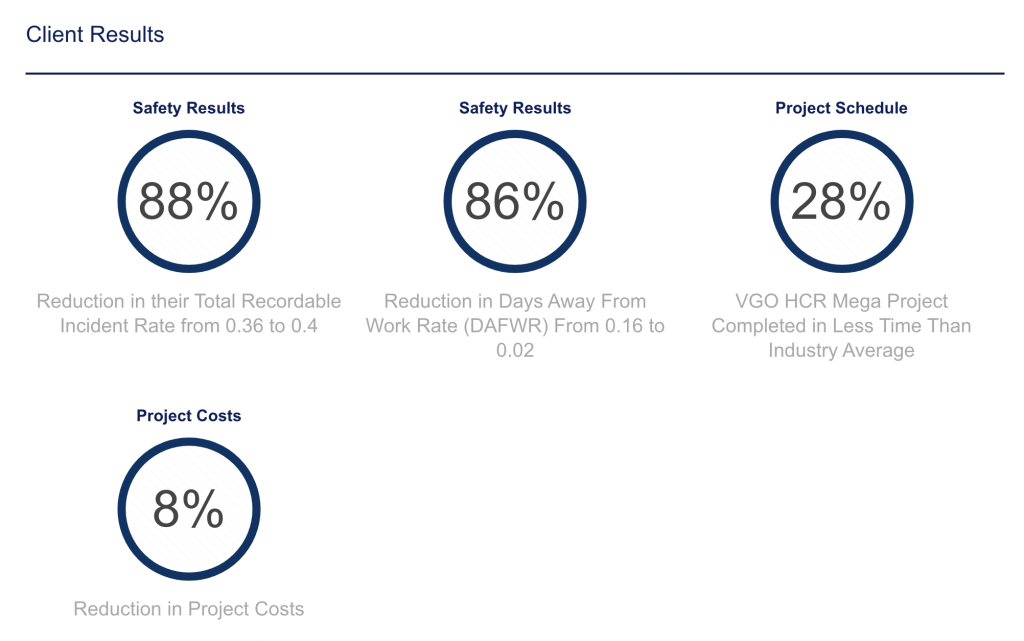

Over the course of the three mega-projects, GS Caltex has seen dramatic results.

Not only were the safety records seeing drastic improvements, the projects themselves have been completed with numbers well under industry average, based on numbers by Independent Project Analysis, Inc. (IPA). The VGO HCR project was completed in 28% less time than the industry average, and its cost was 8% less. The VR HCR project also was completed below average cost and time (final numbers have not been released by IPA).

Over the course of eight years, GS Caltex management remained firm in their safety commitment, and the result has been a transformed culture with workers exhibiting care and concern for their co-workers, mutual trust and respect, and an environment of looking out for one another. There has been a noticeable shift in ownership of the IIF Safety approach as workers across GS Caltex are fully adopting the commitment to safety.

Along with these shifts, facilities have improved. There are more rest areas for workers, rest and welfare facilities have improved, and the overall communication of the culture has shifted from an authoritative culture to a more collaborative culture with open communication, joint safety checks, and safety inspections on site conducted by union and safety leaders.

Not only is this influencing GS Caltex workers, it has also had a major impact on contractors working on the project.