What we do

Leading the way in culture change consulting

For over 35 years, JMJ has been at the forefront of culture change, helping executives, leaders and the frontline achieve breakthrough results in safety, sustainability and business performance. Our approach combines consulting expertise and Transformation Cloud ™ technologies to make the impossible possible.

As a trusted culture change partner to many of the world’s most respected organizations, we have inspired thousands of people working in diverse industries to see things from a different perspective and thrive in their work.

What we offer

How we do it

Innovative technologies and consulting expertise

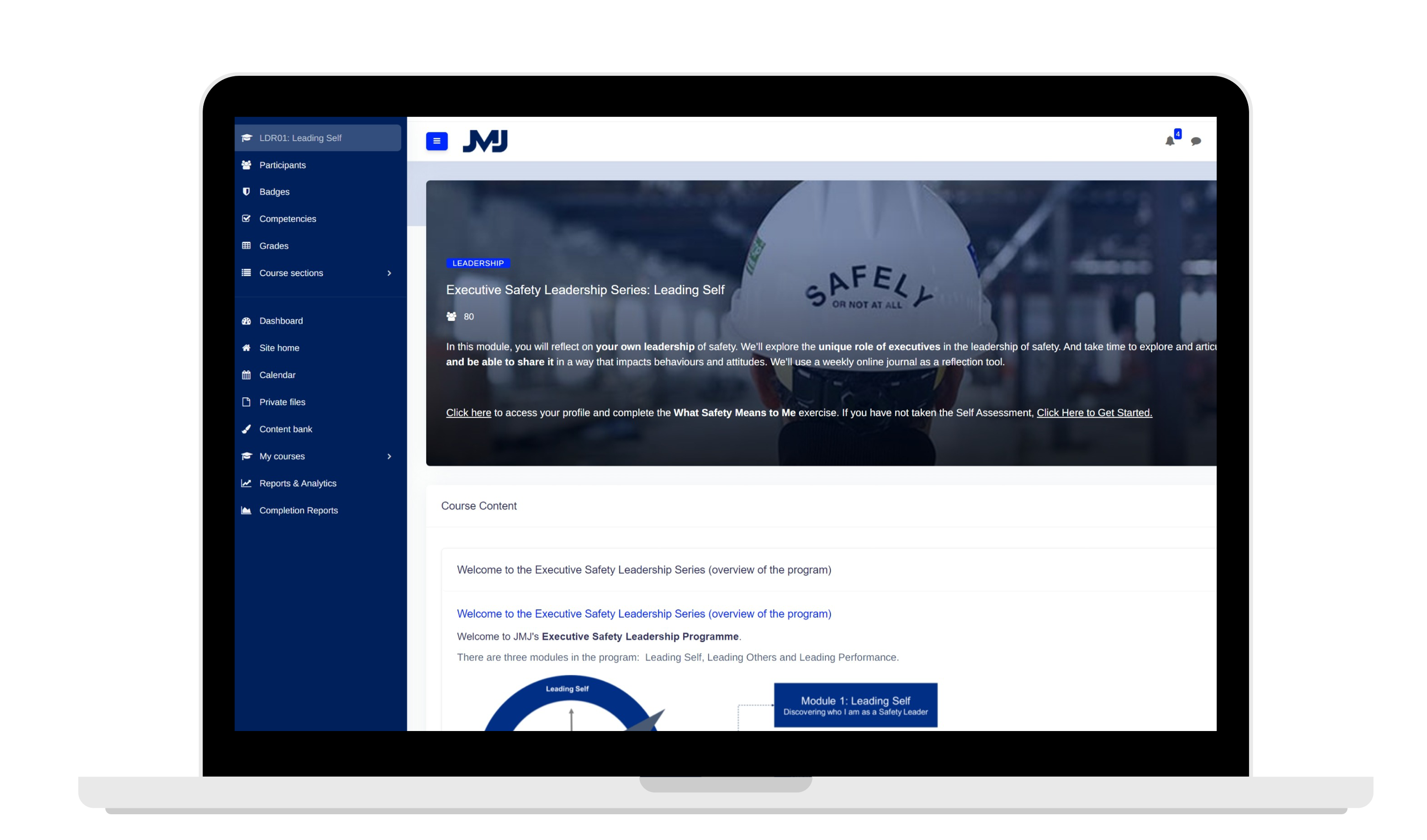

JMJ’s proprietary Transformation Cloud™ technology platform hosts an array of diagnostic and development tools which provide leaders with a comprehensive understanding of their organization’s current culture. JMJ helps clients interpret this data and create a customized blueprint for achieving safety, sustainability and performance goals. Our experienced consultants and proven methodologies ensure success, while the platform’s intuitive interface allows progress to be tracked and maintained over time.

Don’t just take our word for it. Our clients include: